Innovative transfer technique enhances lithium-metal battery safety and durability

Breakthrough in Battery Technology: Korean Researchers Develop New Protective Layer for Lithium-Metal Batteries

A team of researchers in South Korea has made a significant advancement in battery technology by developing a new transfer printing method that creates protective thin layers on lithium metal surfaces. This innovation is designed to address the persistent issue of dendrite formation, which has long hindered the development of next-generation lithium-metal batteries.

The research was conducted by Dr. Jungdon Suk's team at the Advanced Battery Research Center of the Korea Research Institute of Chemical Technology (KRICT). They successfully transferred hybrid protective layers made from solid polymers and ceramics onto lithium metal using a solvent-free process. This breakthrough was published in the journal Energy Storage Materials.

Unlike traditional wet coating methods, this technique allows for uniform coating over large areas without damaging the reactive lithium surface. This development represents a major step forward in making lithium-metal batteries commercially viable.

Lithium-metal batteries are considered a promising energy storage system because they replace graphite with lithium metal as the anode. These batteries have ten times the theoretical capacity of conventional lithium-ion batteries, making them essential for solid-state and lithium-sulfur batteries that require high energy density.

However, the risk of dendrite formation during charge and discharge cycles poses serious safety concerns, including short-circuiting and fire hazards. Additionally, these dendrites can reduce the lifespan of the battery. Traditional wet-coating processes, which use organic solvents, often introduce impurities and damage the lithium surface, complicating large-scale production and commercialization.

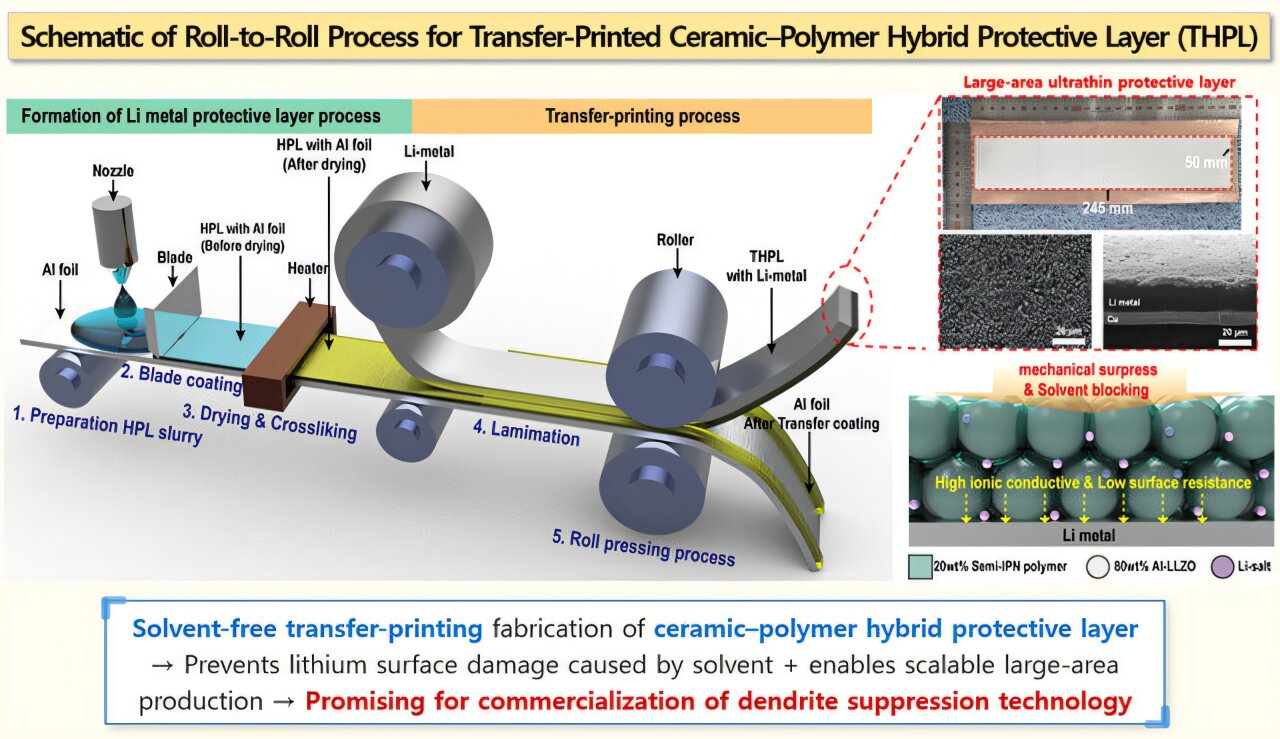

To tackle these challenges, the research team developed two types of protective layers: a dual-layer composed of alumina (Al₂O₃) and gold (Au), and a hybrid layer combining ceramic (Al-LLZO) and polymer components. These layers were then laminated onto lithium metal using a roll-based transfer printing technique, marking the first time this method has been applied in this field.

This technique involves forming the protective layer on a separate substrate and transferring it to lithium using pressure. This eliminates the need for solvents, reduces damage to lithium, and improves the uniformity and reproducibility of the process.

In previous studies, the Al₂O₃–Au dual layer proved effective in suppressing dendrite growth and maintaining stable cycling through its mechanical strength and reduced interfacial resistance. This work was the first to introduce transfer printing as a solution to interface instability and the limitations of wet coating.

Building on this, the research team has now demonstrated a method for transferring ionically conductive, flexible hybrid protective layers over a 245 × 50 mm area with a thickness of just 5 μm. These hybrid layers suppress dendrite growth and induce uniform lithium-ion flux at the interface between the electrode and electrolyte, enabling stable cycling performance.

The uniform transfer of large-area protective films confirms both technological advancement and scalability for commercialization. In pouch-cell tests, the hybrid-protected lithium anode maintained 81.5% capacity retention after 100 charge/discharge cycles, with a low overpotential of 55.34 mV and a high Coulombic efficiency of 99.1%—more than twice the stability of bare lithium cells.

Even under high-rate conditions that fully discharge the battery within nine minutes, the cells retained 74.1% of their initial capacity, demonstrating fast, stable, and efficient cycling characteristics.

The team expects this innovation to accelerate the practical use of lithium-metal batteries in high-energy applications such as electric vehicles and energy storage systems (ESS). Furthermore, the technology may extend to solid-state and lithium-sulfur batteries, further contributing to the advancement of next-generation battery platforms.

“This study combines novel protective materials and a scalable transfer printing process to overcome the critical challenges of interfacial instability and wet-processing limitations in lithium-metal batteries,” said Dr. Suk.

KRICT President Dr. Young-Kuk Lee added, “This represents one of the most practical solutions for enabling high-energy-density lithium-metal batteries and could boost Korea's competitiveness in the global battery industry.”